Coating

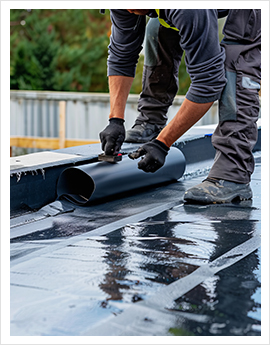

Like painting a car, proper surface preparation is the critical step in roof coatings. Whatever you don’t take care of in the surface preparation, will show up later as a big and potentially very costly mistake when roof leaks cause damage. Proper planning for your roof coating project will keep quality up and costs down.

WE’RE THE ROOF COATINGS EXPERTS

Roof coatings system planning looks at:

- Type of surface

- Proper surface preparation

- Thickness of the base coat

- Ultraviolet (UV) protection requirements

- Topcoat choices and thicknesses

- Application methods

Proper planning for your roof coatings projects will keep quality up and costs down.

ELASTOMERIC/ACRYLIC ROOF COATINGS

Can My Roof Be Coated?

Trademark Restoration specializes in numerous coating/restoration applications. Existing roof systems, such as asphalt built up, modified bitumen, polyurethane foam, single-ply membranes such as EPDM, TPO, PVC, and even metal roofs, can be coated.

A Fraction of the Cost

A coating restoration system is typically a fraction of the cost of a complete roof replacement. Roof coatings can be installed in about half the time that a new roof installation requires and greatly reduces the disruption of the building’s tenants.

Reduce Operating Cost – Go Green

Reducing heat build-up on commercial roofing can dramatically affect building operating costs. Findings reported by the Roofing Manufacturers Association conclude that heat build-up can shorten the useful life of rubber, synthetic polymer, and especially asphalt roofing systems. Cool roof technology utilizing specialized white coatings that reflect the sun’s light before it can be turned into heat significantly reduce temperature. For example, a 95° F day raises black roof top temperature to 170° F, while a white roof would not exceed 120° F — a temperature drop of almost 30%.

Is the roof of the building you’re in dark in color, or even completely black? Changing that color to white could radically improve operating costs; reduce your utility bills, and even benefit the surrounding environment. Properly installed ENERGY STAR rated coatings will as enable the roof to last much longer.

Over time, heat, sunlight, and cracking due to expansion and contraction will degrade a roof. The traditional model was to tear off the aging roof and replace it after 15 or 20 years. Elastomeric coatings can change all that. A coated roof could last the lifetime of the building with regular maintenance which includes occasional cleaning with a hose or power washer and reapplication of additional coatings.

A mere five-year increase in roof service life should reduce the cost of roofing by 21%, cutting landfill waste from roofing. Roofing waste currently represents almost 4% of the total volume of solid wastes in the United States.

Tax Deductible

In most cases, a roof restoration/coating job is 100% tax deductible and you don’t have to amortize it like a capital improvement.

ALUMINUM ROOF COATINGS

Roofs tend to heat to high temperatures under our hot summer sun; typically heating up the inside of the building as well. This added heat requires constant running of air conditioning units, which escalates the cost of maintaining a “cool” temperature inside for your tenants.

The heat from the sun is not only causing the roof and interior of the building to get hot, but the sun’s deteriorating ultra violet rays can be your roof’s worst enemy causing drying, brittleness, splitting, cracking, and/or alligatoring. Over time, these symptoms generally allow for water intrusion into the building.

Aluminum coatings can be an ideal solution to extend the life of your roof. Aluminum coatings provide a highly reflective and seamless sun barrier; all the while saving you energy costs and protecting the environment from roofing materials being dumped into our landfills.

Aluminum coatings help protect against water penetration and damaging leaks. If your roof is left unattended for long a period of time, it’s possible that the deterioration will exceed the limit of normal maintenance and could lead to complete roof replacement, which can be quite expensive.

Aluminum coatings are generally used on the following types of roofs:

- Smooth surface built up roof

- Granulated caphsheet

- Asphalt coated roofing (no gravel)

- An already aluminum coated roof assembly

Aluminum coatings can be up to 8X more reflective than a typical black roof surface and up to 4X more reflective than a typical gravel roof. Aluminum coatings also help protect the roof from “thermal shock”. Thermal shock is when the normal day-to-night temperature fluctuations cause the roof to expand and contract and eventually dry the adhesives and membranes. Aluminum coatings can reduce the temperature fluctuations by as much as 50%, reducing thermal stress and extending the life of the roof.

Aluminum coatings are ideal for protection of newly installed roofs, as well as properly prepared older roofs. Aluminum coatings are applied in numerous application styles, such as using spray equipment, rollers and brushes, and even squeegees.

Aluminum coatings are a dependable waterproofing option in lieu of a complete roof replacement.

(800)293-0221

(800)293-0221